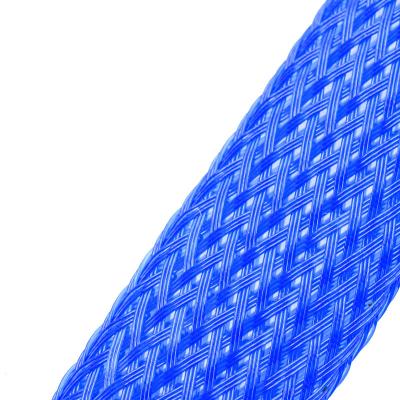

Nomex Braided Sleeving

Nomex sleeving braided with nomex multifilament fibres. This light weight braided product exhibits an exceptional thermal stability and chemical, solvent and abrasion resistance.

The sleeving retains its integrity at temperatures over 245°C, (the melting point of Nylon) or in presence of Beta, gamma and X-ray radiation or when exposed to high humidity or moisture. The expandable construction allows the sleeving to be easily drawn on long lengths of wiring and cover a wide range of diameters with only a few product sizes.

It has been used for years by race car drivers, fire departments, and oil rig personnel to provide that extra level of protection from the dangers that come with working in and around intense flame and heat. Flexo Nomex braided sleeving will do the same for your wires, hoses, and cables.

Feactures and benefits

1.Operating temperature range: -196° to 350°C

2.Cuts easily with scissors

3.Abrasion and cut resistant

4.Soft, pliable & strong

5.Resists common chemicals & solvents

6.Expands slightly for easy installation

7.Tight braid for full coverage and protection

8.Melt temperature:1120°C

Physical properties

| Material |

Nomex (Polyaryl-mide) |

| Working temperature |

-196° to 350°C |

| Melt point |

1120°C |

| Standard color |

Army green,white |

| Certification | Rohs,halogen free |

| Cutting tool | Scissor |

|

Tensile strength at break |

Conditioned at 65%. RH: 4.4cN/dtex. Wet: 3.5cN dtex. |

|

Elongation at break |

Conditioned at 65% RH; 25% Wet; 16% |

|

Initial modulus at 100% elongation |

Conditioned at 65% RH: 110cN/dtex |

|

Fibre |

200 Derniers (220dtex) |

|

Specific gravity |

1.38 |

| Flammability |

UL94-V0 |

|

Chemical resistance |

Mineral acids, organic acids, alkalis, cleaning agents, salt solutions, unaffected by Freon, Gasoline, Jet Fuel, Ethylene Glycol and Methyl Alcohol. |

Application

Nomex sleeves used for a wide range of applications such as military, aerospace, race car, fire department to protect the cable and wire from the dangers that come with working in and around intense flame and heat.

Specification

| Part No |

Size (mm) |

Expansion Range(mm) | Packing Length | |

| Min.(I) | Max.(O) | |||

| MJ-NMBS003 | 3.0 | 1.0 | 4.0 | 500m/spool |

|

MJ-NMBS006 |

6.0 | 5.0 | 8.0 | 300m/spool |

|

MJ-NMBS008 |

8.0 | 6.0 | 10.0 | 250m/spool |

|

MJ-NMBS010 |

10.0 | 7.0 | 13.0 | 200m/spool |

|

MJ-NMBS012 |

12.0 | 8.0 | 16.0 | 200m/spool |

|

MJ-NMBS015 |

15.0 | 10.0 | 20.0 | 200m/spool |

|

MJ-NMBS020 |

20.0 | 14.0 | 26.0 | 150m/spool |

|

MJ-NMBS025 |

25.0 | 18.0 | 33.0 | 150m/spool |

|

MJ-NMBS030 |

30.0 | 20.0 | 39.0 | 100m/spool |

|

MJ-NMBS040 |

40.0 | 30.0 | 52.0 | 100m/spool |

|

MJ-NMBS050 |

50.0 | 50.0 | 65.0 | 100m/spool |

English

English