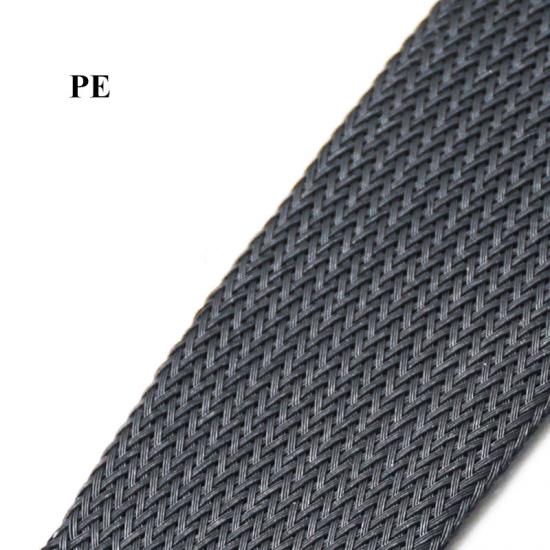

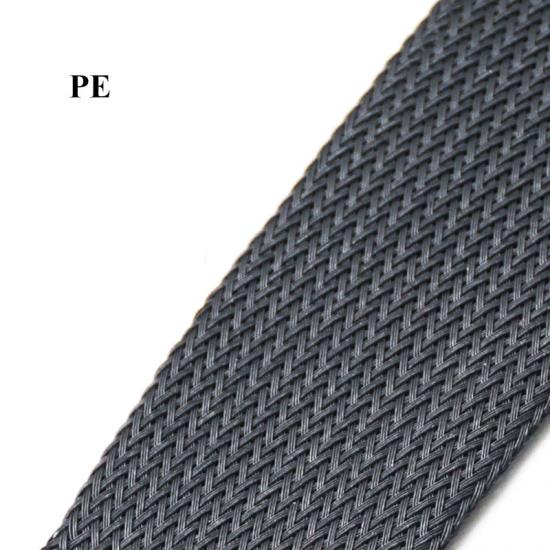

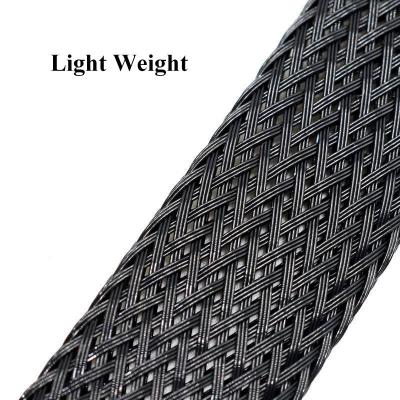

Protection PE expandable braided sleeving

PE braided sleeving is a type of protective covering made from polyethylene material that braided into a tubular shape, usually used for protecting cables and wires.

Certifications

What's special about PE braid sleeve?

1.Made of polyethylene (PE)

2.Keeps it's flexibility under a wide range of temperatures

3.Economical & easy to install

4.Cut & abrasion resistant

PE (polyethylene) braided sleeving finds a wide range of applications across various industries due to its protective and organizational properties.

Specification

|

Specification |

Number of strands

|

Dia of single strand(mm) |

Number of ingot |

Flat width (mm) |

Mesh number |

Cut length (mm) |

Extended range

I~O(mm)

|

|

BRS-PE-038-BK |

3 |

0.27±0.02 |

120 |

38±5 |

9±1 |

Custom length |

30~52 |

Application

PE braided sleeving is commonly used for cable management, organization, and protection in various applications, particularly in the field of electronics, wiring, and industrial settings. It helps prevent tangling, abrasion, and damage to delicate wiring, improving the overall reliability of electronic systems. In the automotive industry, PE braided sleeving is employed to bundle and shield wiring harnesses, protecting them from heat, moisture, chemicals, and mechanical stress. The aerospace sector utilizes PE braided sleeving to safeguard cables and wiring in aircraft and spacecraft.The sleeving helps maintain signal integrity and prevents interference while withstanding the harsh conditions of flight. In industrial settings, PE braided sleeving is used to protect and organize cables in machinery, conveyor systems, robotics, and manufacturing equipment.It helps reduce downtime by preventing cable damage.

English

English