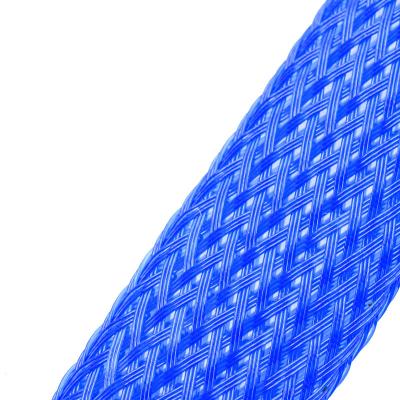

EMI Shielding Expandable Braided Sleeving

Emi wire shielding sleeve is made of tinned copper wire and polyester monofilament mix braiding, it’s specially designed for mechanical wear resistance and anti-electromagnetic for the automotive wire harness. The important feature is that it’s more suitable for operating in the narrow space because of the material’s high flexibility, meanwhile it is much lighter, softer and cost effective than the normal tinned copper sleeving.

Feactures and benefits

1.Excellent electromagnetic protection

2.Extremely flexible, expandable and easy to apply

3.No kinks or ruptures even when bent at sharp angles

4.Superior abrasion protection

5.Particularly suitable for applications with restricted space or requiring movement

6.Inner disposable tube protects sleeve from deformation and allows for easy insertion of cables

7.Fulfils the requirements for radio disturbances in vehicles, boats and engines

Physical properties

| Material | Tinned copper yarn+polyester monofilament |

| Working temperature |

-50℃~+150℃ |

| Melt point |

240±10℃ |

|

Flammability |

FMVSS302 |

|

Color |

Black/silver |

| Certification | Rohs |

| Cutting tool | Scissor |

Application

Braided EMI shield sleeves are perfect for applications where shielding is critical and flexing is brutal, such as:

|

Telecommunications equipment |

Test and measurement equipment |

|

Laptop computer lids |

Printers, plotters and copiers |

|

Automotive equipment |

Medical equipment |

Specification

| Part No | Size | Expanded Range(mm) | Packing Length | ||

| Inch | mm | Min(I) | Max(O) | ||

| MJ-EMIBS006 | 1/4" | 6 | 3 | 8 | 200m/spool |

| MJ-EMIBS008 | 5/16" | 8 | 5 | 13 | 200m/spool |

| MJ-EMIBS010 | 3/8" | 10 | 7 | 16 | 150m/spool |

| MJ-EMIBS012 | 1/2" | 12 | 8 | 20 | 150m/spool |

| MJ-EMIBS016 | 5/8" | 16 | 10 | 24 | 100m/spool |

| MJ-EMIBS019 | 3/4" | 19 | 14 | 30 | 100m/spool |

English

English