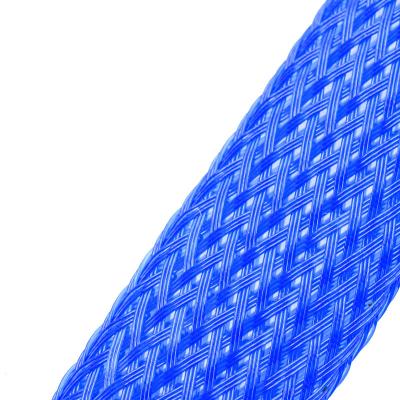

Silicone Rubber Coated Fiberglass Sleeving

Silicone fiberglass sleeving is engineered with a silicone rubber coating over an insulating fiberglass sleeve. Silicone coated fiberglass sleeving is very abrasion resistant and is ideal in heavy duty applications that require outstanding mechanical and electrical properties.

Silicone coated fiberglass sleeving has a high tear strength, slight expandability for easy installation, excellent flex life and resistance to fatigue.

Certifications

Feactures and benefits

1.Class H (200°C) insulating material.

2.Grade A up to 7 kV,grade B up to 4 kV

3.Light,soft and fliexble

4.Available in different sizes

5.Resists corrosion

6.Anti-aging protective

7.Chemical resistance

8.Self-extinguishing

Physical Properties

| Sleeve material | Fiberglass fiber |

| Coated material | Silicone rubber |

| Working Temperature |

-50℃ to 200℃ |

| Temperature endurance | 265℃+(-)2℃ |

| Aging Test | 6 hours without crackle |

| Cold bend | Without crackle |

|

Voltage Rating |

4.0KV,7.0KV |

|

Flammability |

VW-1 |

| Standard Color | White,Black |

| Colored | Available |

| Certification | UL,ROHS,Reach |

| Cutting Tool | Scissor |

Specification

| Part No |

Size ID (mm) |

ID Tolerance (mm) |

Wall Thickness(T) (mm) |

Packing Length (m/spool) |

|||

| 1.5KV | 2.5KV | 4KV | 7KV | ||||

| MJ-FGS-0.5 | 0.5 | +0.20/-0.0 | 0.28±0.05 | 0.30±0.05 | 0.40±0.05 | 0.45±0.08 | 200 |

| MJ-FGS-0.8 | 0.8 | +0.20/-0.0 | 0.28±0.05 | 0.30±0.05 | 0.40±0.05 | 0.45±0.08 | 200 |

| MJ-FGS-1.0 | 1.0 | +0.20/-0.0 | 0.28±0.05 | 0.30±0.05 | 0.40±0.05 | 0.45±0.08 | 200 |

| MJ-FGS-1.5 | 1.5 | +0.20/-0.0 | 0.28±0.05 | 0.30±0.05 | 0.40±0.05 | 0.50±0.08 | 200 |

| MJ-FGS-2.0 | 2.0 | +0.20/-0.0 | 0.28±0.05 | 0.30±0.05 | 0.40±0.05 | 0.50±0.08 | 200 |

| MJ-FGS-2.5 | 2.5 | +0.25/-0.0 | 0.30±0.05 | 0.35±0.05 | 0.45±0.05 | 0.55±0.08 | 200 |

| MJ-FGS-3.0 | 3.0 | +0.25/-0.0 | 0.30±0.05 | 0.35±0.05 | 0.45±0.05 | 0.55±0.08 | 100 |

| MJ-FGS-3.5 | 3.5 | +0.35/-0.0 | 0.30±0.05 | 0.35±0.05 | 0.45±0.05 | 0.55±0.08 | 100 |

| MJ-FGS-4.0 | 4.0 | +0.35/-0.0 | 0.30±0.05 | 0.35±0.05 | 0.45±0.05 | 0.55±0.08 | 100 |

| MJ-FGS-4.5 | 4.5 | +0.35/-0.0 | 0.30±0.05 | 0.35±0.05 | 0.45±0.05 | 0.55±0.08 | 100 |

| MJ-FGS-5.0 | 5.0 | +0.35/-0.0 | 0.30±0.05 | 0.35±0.05 | 0.45±0.05 | 0.55±0.08 | 100 |

| MJ-FGS-5.5 | 5.5 | +0.35/-0.0 | 0.30±0.05 | 0.35±0.05 | 0.45±0.05 | 0.55±0.08 | 100 |

| MJ-FGS-6.0 | 6.0 | +0.50/-0.0 | 0.35±0.05 | 0.40±0.05 | 0.55±0.05 | 0.60±0.08 | 100 |

| MJ-FGS-6.5 | 6.5 | +0.50/-0.0 | 0.35±0.05 | 0.40±0.05 | 0.55±0.05 | 0.60±0.08 | 100 |

| MJ-FGS-7.0 | 7.0 | +0.50/-0.0 | 0.35±0.05 | 0.40±0.05 | 0.55±0.05 | 0.60±0.08 | 100 |

| MJ-FGS-7.5 | 7.5 | +0.50/-0.0 | 0.35±0.05 | 0.40±0.05 | 0.55±0.05 | 0.60±0.08 | 100 |

| MJ-FGS-8.0 | 8.0 | +0.50/-0.0 | 0.35±0.05 | 0.40±0.05 | 0.55±0.05 | 0.60±0.08 | 50 |

| MJ-FGS-8.5 | 8.5 | +0.50/-0.0 | 0.35±0.05 | 0.40±0.05 | 0.55±0.05 | 0.60±0.08 | 50 |

| MJ-FGS-9.0 | 9.0 | +0.50/-0.0 | 0.35±0.05 | 0.40±0.05 | 0.55±0.05 | 0.60±0.08 | 50 |

| MJ-FGS-10.0 | 10.0 | +0.70/-0.0 | 0.45±0.05 | 0.50±0.05 | 0.60±0.05 | 0.65±0.08 | 50 |

| MJ-FGS-11.0 | 11.0 | +0.70/-0.0 | 0.45±0.05 | 0.50±0.05 | 0.60±0.05 | 0.65±0.08 | 50 |

| MJ-FGS-12.0 | 12.0 | +0.70/-0.0 | 0.45±0.05 | 0.50±0.05 | 0.60±0.05 | 0.65±0.08 | 50 |

| MJ-FGS-13.0 | 13.0 | +0.80/-0.0 | 0.45±0.05 | 0.50±0.05 | 0.60±0.05 | 0.65±0.08 | 50 |

| MJ-FGS-14.0 | 14.0 | +0.80/-0.0 | 0.45±0.05 | 0.50±0.05 | 0.60±0.05 | 0.65±0.08 | 50 |

| MJ-FGS-15.0 | 15.0 | +0.80/-0.0 | 0.45±0.05 | 0.50±0.05 | 0.60±0.05 | 0.65±0.08 | 50 |

| MJ-FGS-16.0 | 16.0 | +0.80/-0.0 | 0.45±0.05 | 0.50±0.05 | 0.60±0.05 | 0.65±0.08 | 50 |

| MJ-FGS-17.0 | 17.0 | +0.80/-0.0 | 0.53±0.08 | 0.55±0.08 | 0.65±0.10 | 0.70±0.10 | 50 |

| MJ-FGS-18.0 | 18.0 | +0.80/-0.0 | 0.53±0.08 | 0.55±0.08 | 0.65±0.10 | 0.70±0.10 | 50 |

| MJ-FGS-19.0 | 19.0 | +0.80/-0.0 | 0.53±0.08 | 0.55±0.08 | 0.65±0.10 | 0.70±0.10 | 50 |

| MJ-FGS-20.0 | 20.0 | +0.80/-0.0 | 0.53±0.08 | 0.55±0.08 | 0.65±0.10 | 0.70±0.10 | 50 |

| MJ-FGS-22.0 | 22.0 | +1.00/-0.0 | 0.60±0.08 | 0.65±0.10 | 0.75±0.10 | 0.80±0.10 | 25 |

| MJ-FGS-25.0 | 25.0 | +1.00/-0.0 | 0.53±0.05 | 0.65±0.10 | 0.75±0.10 | 0.80±0.10 | 25 |

Application

The mechanical properties and strength of Silicone coated fiberglass make it a great choice in applications such as:

1.Transformer lead protection

2.Motor coil leads

3.Component isolation

4.Power supply wiring

English

English