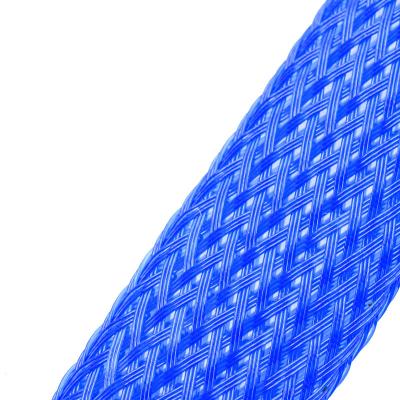

Silicone Coated Fiberglass Braided Wire Insulation Sleeving

Silicone coated fiberglass sleeve made of fiberglass, coated with silicone resin, heated and plasticized, possessing good wear resistance, insulation, high-temperature resistance,corrosion resistance,anti-aging etc.

Fiberglass sleeve applied to mechanization, electrical and office devices, has good heat protection on the cables.

It's a heat insulation protection for wires near the engine and the spark plug of the vehicle. It has good flexibility and will not be damaged due to dryness. Anti-aging, durable, and long service life.

Fiberglass insulation sleeve wildly used in heat insulation and fire protection of vehicle pipelines, mainly for self-heating or pipelines close to the heat source, such as automotive fuel pipes, vacuum tubes, exhaust pipes, etc..

Certifications

What's special about fiberglass cable sleeve?

1.Made of fiberglass fiber,coated with silicone resin

2.Light,soft and fliexble

3.Available in different sizes

4.Resists corrosion

5.Anti-aging protective

6.Heat insulation protection

7.Chemical resistance

8.Self-extinguishing

Physical Properties

| Sleeve | Fiberglass fiber |

| Coated | Silicone resin |

| Working Temperature |

-50℃ to 200℃ |

|

Voltage Rating |

1.5KV,2.5KV,4.0KV |

|

Flammability |

VW-1 |

| Standard Color | White |

| Colored | Available |

| Certification | UL,ROHS |

| Cutting Tool | Scissor |

Specification

| Part No |

Size ID (mm) |

ID Tolerance (mm) |

Wall Thickness(T) (mm) |

Packing Length (m/spool) |

|||

| 1.5KV | 2.5KV | 4KV | 7KV | ||||

| MJ-FGS-0.5 | 0.5 | +0.20/-0.0 | 0.28±0.05 | 0.30±0.05 | 0.40±0.05 | 0.45±0.08 | 200 |

| MJ-FGS-0.8 | 0.8 | +0.20/-0.0 | 0.28±0.05 | 0.30±0.05 | 0.40±0.05 | 0.45±0.08 | 200 |

| MJ-FGS-1.0 | 1.0 | +0.20/-0.0 | 0.28±0.05 | 0.30±0.05 | 0.40±0.05 | 0.45±0.08 | 200 |

| MJ-FGS-1.5 | 1.5 | +0.20/-0.0 | 0.28±0.05 | 0.30±0.05 | 0.40±0.05 | 0.50±0.08 | 200 |

| MJ-FGS-2.0 | 2.0 | +0.20/-0.0 | 0.28±0.05 | 0.30±0.05 | 0.40±0.05 | 0.50±0.08 | 200 |

| MJ-FGS-2.5 | 2.5 | +0.25/-0.0 | 0.30±0.05 | 0.35±0.05 | 0.45±0.05 | 0.55±0.08 | 200 |

| MJ-FGS-3.0 | 3.0 | +0.25/-0.0 | 0.30±0.05 | 0.35±0.05 | 0.45±0.05 | 0.55±0.08 | 100 |

| MJ-FGS-3.5 | 3.5 | +0.35/-0.0 | 0.30±0.05 | 0.35±0.05 | 0.45±0.05 | 0.55±0.08 | 100 |

| MJ-FGS-4.0 | 4.0 | +0.35/-0.0 | 0.30±0.05 | 0.35±0.05 | 0.45±0.05 | 0.55±0.08 | 100 |

| MJ-FGS-4.5 | 4.5 | +0.35/-0.0 | 0.30±0.05 | 0.35±0.05 | 0.45±0.05 | 0.55±0.08 | 100 |

| MJ-FGS-5.0 | 5.0 | +0.35/-0.0 | 0.30±0.05 | 0.35±0.05 | 0.45±0.05 | 0.55±0.08 | 100 |

| MJ-FGS-5.5 | 5.5 | +0.35/-0.0 | 0.30±0.05 | 0.35±0.05 | 0.45±0.05 | 0.55±0.08 | 100 |

| MJ-FGS-6.0 | 6.0 | +0.50/-0.0 | 0.35±0.05 | 0.40±0.05 | 0.55±0.05 | 0.60±0.08 | 100 |

| MJ-FGS-6.5 | 6.5 | +0.50/-0.0 | 0.35±0.05 | 0.40±0.05 | 0.55±0.05 | 0.60±0.08 | 100 |

| MJ-FGS-7.0 | 7.0 | +0.50/-0.0 | 0.35±0.05 | 0.40±0.05 | 0.55±0.05 | 0.60±0.08 | 100 |

| MJ-FGS-7.5 | 7.5 | +0.50/-0.0 | 0.35±0.05 | 0.40±0.05 | 0.55±0.05 | 0.60±0.08 | 100 |

| MJ-FGS-8.0 | 8.0 | +0.50/-0.0 | 0.35±0.05 | 0.40±0.05 | 0.55±0.05 | 0.60±0.08 | 50 |

| MJ-FGS-8.5 | 8.5 | +0.50/-0.0 | 0.35±0.05 | 0.40±0.05 | 0.55±0.05 | 0.60±0.08 | 50 |

| MJ-FGS-9.0 | 9.0 | +0.50/-0.0 | 0.35±0.05 | 0.40±0.05 | 0.55±0.05 | 0.60±0.08 | 50 |

| MJ-FGS-10.0 | 10.0 | +0.70/-0.0 | 0.45±0.05 | 0.50±0.05 | 0.60±0.05 | 0.65±0.08 | 50 |

| MJ-FGS-11.0 | 11.0 | +0.70/-0.0 | 0.45±0.05 | 0.50±0.05 | 0.60±0.05 | 0.65±0.08 | 50 |

| MJ-FGS-12.0 | 12.0 | +0.70/-0.0 | 0.45±0.05 | 0.50±0.05 | 0.60±0.05 | 0.65±0.08 | 50 |

| MJ-FGS-13.0 | 13.0 | +0.80/-0.0 | 0.45±0.05 | 0.50±0.05 | 0.60±0.05 | 0.65±0.08 | 50 |

| MJ-FGS-14.0 | 14.0 | +0.80/-0.0 | 0.45±0.05 | 0.50±0.05 | 0.60±0.05 | 0.65±0.08 | 50 |

| MJ-FGS-15.0 | 15.0 | +0.80/-0.0 | 0.45±0.05 | 0.50±0.05 | 0.60±0.05 | 0.65±0.08 | 50 |

| MJ-FGS-16.0 | 16.0 | +0.80/-0.0 | 0.45±0.05 | 0.50±0.05 | 0.60±0.05 | 0.65±0.08 | 50 |

| MJ-FGS-17.0 | 17.0 | +0.80/-0.0 | 0.53±0.08 | 0.55±0.08 | 0.65±0.10 | 0.70±0.10 | 50 |

| MJ-FGS-18.0 | 18.0 | +0.80/-0.0 | 0.53±0.08 | 0.55±0.08 | 0.65±0.10 | 0.70±0.10 | 50 |

| MJ-FGS-19.0 | 19.0 | +0.80/-0.0 | 0.53±0.08 | 0.55±0.08 | 0.65±0.10 | 0.70±0.10 | 50 |

| MJ-FGS-20.0 | 20.0 | +0.80/-0.0 | 0.53±0.08 | 0.55±0.08 | 0.65±0.10 | 0.70±0.10 | 50 |

| MJ-FGS-22.0 | 22.0 | +1.00/-0.0 | 0.60±0.08 | 0.65±0.10 | 0.75±0.10 | 0.80±0.10 | 25 |

| MJ-FGS-25.0 | 25.0 | +1.00/-0.0 | 0.53±0.05 | 0.65±0.10 | 0.75±0.10 | 0.80±0.10 | 25 |

Application

Fiberglass braided sleeving suitable for various electrical insulation and bonding of cables and connectors, and are widely used in connection or termination. It mainly used for wire connection, solder joint protection, electronic equipment protection and insulation treatment, metal surface protection, etc.

English

English